The module PACK automatic assembly line is a production line used for automated assembly of battery modules, which can achieve efficient, precise, and stable production of battery modules. The following is a general introduction to the module PACK automatic assembly line:

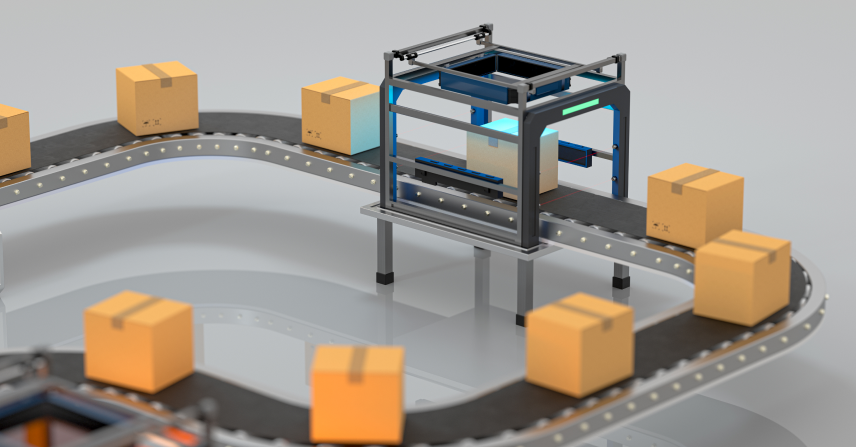

1. Conveyor system: Automatic assembly lines typically include a conveyor system used to transport battery cells and other components from one workstation to another, in order to achieve a continuous production process.

2. Sorting and assembly of battery cells: Automated equipment is used to sort battery cells, match them based on performance parameters such as voltage, capacity, etc., and then assemble them into specified module structures.

3. Installation of Battery Management System (BMS): Robots or other automated equipment on the automatic assembly line can accurately install and connect BMS to achieve monitoring and management of battery cells.

4. Welding and connection: By using automated welding equipment or other connection technologies, battery cells and other components are connected together to form the structure of a battery module.

5. Temperature control: In the automatic assembly line, temperature sensors and temperature control devices can be integrated to monitor and control the temperature of battery modules to ensure they operate within a safe range.

6. Testing and Quality Inspection: The testing equipment on the automatic assembly line can conduct strict testing and quality inspection on battery modules, including testing of parameters such as voltage, capacity, and internal resistance, to ensure that product quality and performance meet standard requirements.

7. Data recording and traceability: Automatic assembly lines are usually equipped with data recording systems to record and trace the production data of each battery module for quality tracking and management.

8. Automation control and monitoring: The automation control system on the automatic assembly line can achieve automatic control and monitoring of the entire production process to improve production efficiency and product stability.

The application of module PACK automatic assembly line can greatly improve the production efficiency and quality of battery modules, reduce manual operation errors and labor intensity, and provide higher consistency and reliability.